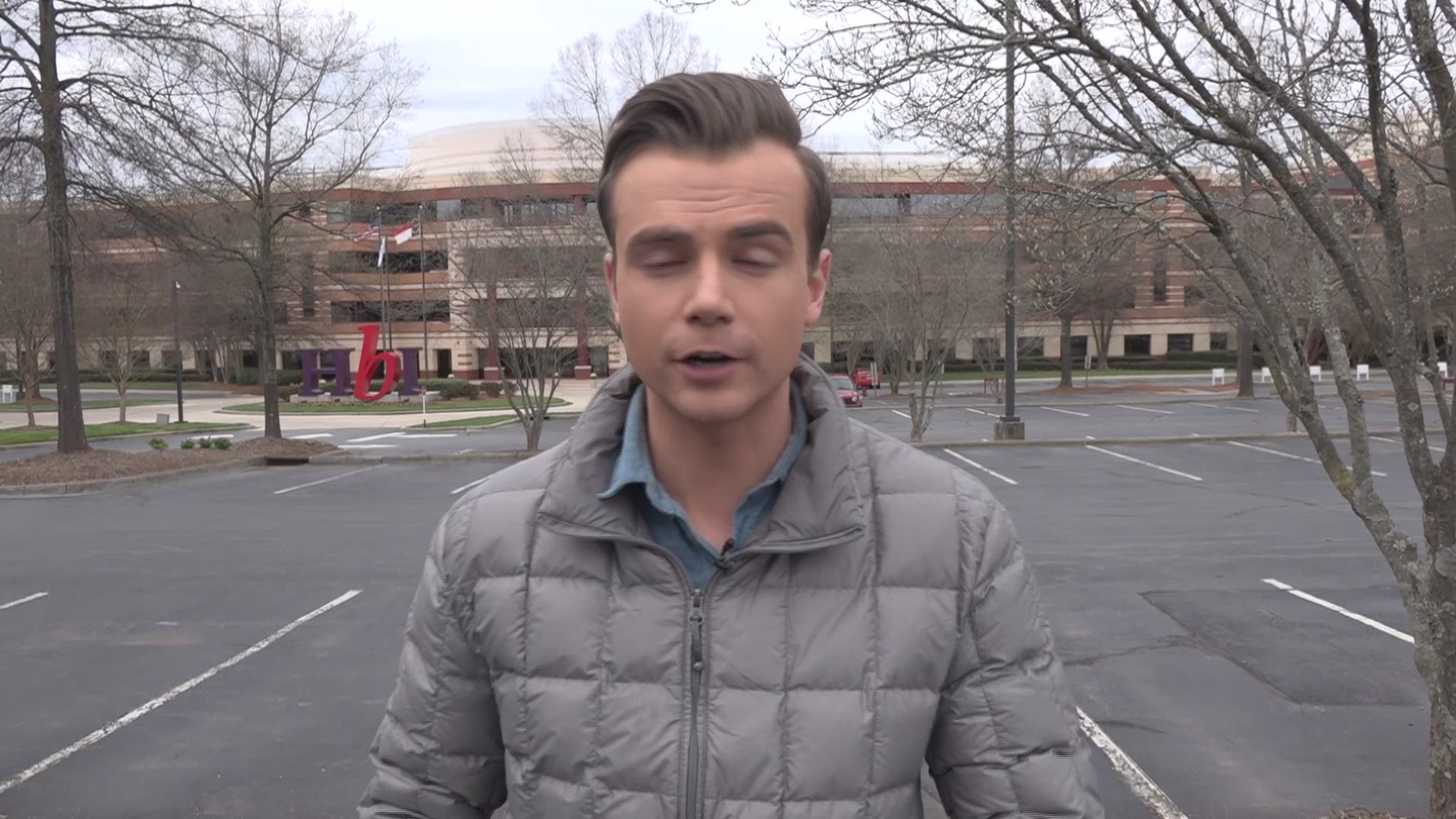

HanesBrands is converting the production of apparel to the production of cotton masks approved by the Federal Drug Administration. According to a statement from the company, HanesBrands is manufacturing the masks under contract with the U.S. federal government.

President Donald Trump announced the move in a coronavirus press briefing on Friday.

A HanesBrands spokesperson told WFMY News 2 that the company was asked by the U.S. Department of Health and Human Services on Friday, March 13 if it could begin creating cotton face masks to address shortages.

"We started initial production in the last few days. It will take weeks to ramp up. We want to ramp up to about 1.5 million masks per week," said Matt Hall, HanesBrands communication director. "We've got people working around the clock tirelessly to make this happen."

The company has joined other major apparel manufacturers that are dedicating manufacturing capacity to meet the U.S. need for masks during the COVID-19 crisis.

So far, the production of the masks has been a huge success according to the written statement WFMY News 2 received from the company.

"The dedication and expertise of HanesBrands supply chain and R&D employees allowed the company to progress from preliminary discussions with federal officials to product development, approval and startup of production in less than one week, a remarkable feat," the statement said.

The company plans to increase production, according to the statement.

"The company expects to ramp up to production of 1.5 million masks weekly, and the consortium as a whole is expected to ramp up to production of 5 million to 6 million masks weekly using HanesBrands’ design and patterns," the statement said.

The first step to creating the masks was designing a prototype, which was then approved by the FDA in a matter of days.

HanesBrands is using cotton yarn spun made from U.S.-grown cotton by its partner Parkdale Mills America. HanesBrands is then using the yarn to make cotton fabric in its large textile manufacturing plants in El Salvador and the Dominican Republic.

From there its using the fabric to make the masks to specification in company-owned sewing facilities in El Salvador, Honduras, and the Dominican Republic.

According to the statement, they are also working with other companies on the specifications on the FDA approved masks.

"In addition to Parkdale Mills America, HanesBrands is working closely with Fruit of the Loom, SanMar, Beverly Knits, the National Council of Textile Organizations, and other apparel companies to share product specifications and patterns for the FDA-approved masks."

The last time the company was involved in anything remotely similar was during World War II, according to the communications director. The company was involved in producing special vests for communication pigeons during the war.

Other Stories: